In today’s world, where innovation and performance are paramount, materials that combine strength, durability, and lightness are more valuable than ever. One such material—carbon fiber—has revolutionized industries from aerospace to medical technology. But what exactly is it, and why do many consider it the material of the future?

What is Carbon Fiber?

Carbon fiber is a high-performance material composed of extremely thin fibers—about 5 to 10 microns in diameter—primarily consisting of carbon atoms. The bonding of these atoms in a crystalline structure gives the fiber its remarkable strength and stiffness.

The process of making it involves heating a precursor material (usually PAN: polyacrylonitrile) to very high temperatures in an oxygen-free environment. The result is a lightweight, incredibly strong fiber that manufacturers weave into fabrics or combine with resins to create composite materials.

Key Properties of Carbon Fiber

One of the reasons carbon fiber is so widely used is its combination of unique properties:

- Lightweight and Strong: In addition, it is significantly lighter than steel or aluminum, yet it can be up to five times stronger.

- High Stiffness: It resists deformation under stress, making it ideal for structural components.

- Corrosion Resistant: Moreover, unlike metal, it doesn’t rust or corrode—even in harsh environments.

- Heat Tolerance: It performs well under high temperatures, depending on the resin used.

- Fatigue Resistance: maintains performance over long-term use and repeated stress.

- Electrical Conductivity: In some forms, it conducts electricity, useful in electronics and aerospace.

Applications Across Industries

Carbon fiber has found its way into a wide range of industries thanks to these properties:

- Aerospace & Defense: Used in aircraft components, drones, and satellites to reduce weight and improve fuel efficiency.

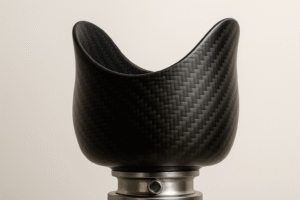

- Automotive: High-performance cars use it for body panels, frames, and interior parts.

- Medical Devices: Innovations like the NekSpine™ wearable support system use it for ergonomic, lightweight support in surgical environments.

- Sports Equipment: Bicycles, tennis rackets, and golf clubs benefit from carbon fiber’s lightweight strength.

- Industrial Use: Machinery and tools often integrate this material for enhanced durability and lower maintenance.

Why It’s the Material of the Future

As industries move toward efficiency, performance, and sustainability, carbon fiber stands out as a solution to many engineering challenges:

- Efficiency Gains: Lightweight materials help reduce fuel consumption and increase performance.

- Sustainability: Less material and energy are required for high-strength output.

- Innovation Potential: composites and hybrids are opening doors to new product designs and uses.

As a result, whether you’re in aerospace, healthcare, automotive, or industrial manufacturing, understanding the benefits of carbon fiber can help you design smarter, stronger, and more sustainable products.

Interested in integrating carbon fiber into your next project?

Explore our product solutions or contact us to learn more.