The Future of Manufacturing Begins with Carbon Fiber Innovations

As industries across aerospace, automotive, energy, and medical sectors evolve, one material continues to stand at the forefront of advanced engineering: carbon fiber. Known for its exceptional strength-to-weight ratio and resistance to corrosion and fatigue, carbon fiber has become indispensable to high-performance applications. But what truly sets today’s material apart is the wave of technological innovations in carbon fiber production.

From enhanced polymer matrix development to AI-driven quality control, the manufacturing process is undergoing a transformation. These carbon fiber innovations are not only increasing efficiency and performance but also reshaping how industries think about lightweight structural materials. Staying updated on these trends is essential for engineers, designers, and manufacturers aiming to lead in a competitive global market.

Precision Through Automation: The Role of Robotics in Carbon Fiber Manufacturing

One of the most impactful shifts in carbon fiber production is the integration of robotic automation. Advanced fiber placement machines now offer unmatched precision, laying out fibers in complex geometries with minimal waste. These machines, guided by algorithms and real-time feedback systems, significantly reduce labor time and ensure product uniformity.

Automation also enables continuous production processes, decreasing turnaround times and lowering overall costs. In high-demand sectors like automotive manufacturing, this makes carbon fiber components not just viable, but scalable. These technological advances are pushing carbon fiber from niche applications into mainstream use.

AI and Machine Learning: Driving Smarter Material Engineering

Another cornerstone of recent progress is the implementation of artificial intelligence in the monitoring and optimization of production lines. Machine learning models are now trained to detect microdefects, forecast material behavior, and even suggest adjustments in curing or weaving processes based on real-time data.

These carbon fiber technology applications not only improve consistency and reduce human error, but also support sustainability by minimizing waste. With AI assistance, manufacturers are achieving new levels of precision and efficiency, ensuring the material meets strict performance standards without excessive resource consumption.

Want to stay ahead of the curve? At CarbonFiber.com, we offer access to cutting-edge carbon fiber materials produced through these very innovations. Explore our products and discover what next-generation performance feels like.

Sustainability as a Driving Force Behind Innovation

Environmental responsibility is no longer optional—it’s driving R&D across the industry. Innovations in carbon fiber production are increasingly focused on sustainability: recycling composite waste, using bio-based resins, and developing energy-efficient curing technologies. These breakthroughs are not only reducing environmental impact but also appealing to industries that require ESG compliance.

Advanced pyrolysis methods now allow for recovery and reuse of fibers without significant loss of mechanical properties. Additionally, low-energy production systems are being developed to shrink the carbon footprint of traditional carbon fiber manufacturing. These sustainable technology innovations are opening new doors for carbon fiber in green energy, electric transportation, and circular design systems.

Hybrid Composites: Redefining Performance Parameters

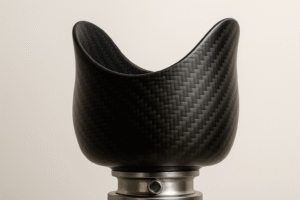

The next frontier in carbon fiber innovations lies in hybrid composite structures. By blending carbon fiber with other materials like Kevlar, fiberglass, or thermoplastics, manufacturers can tailor mechanical properties to meet specific application requirements. This expands the functional versatility of carbon fiber and allows for breakthroughs in aerospace, prosthetics, protective gear, and high-performance sporting goods.

These hybrid materials are especially useful in situations where one property (such as stiffness) must be balanced with another (like impact resistance). Through advanced manufacturing technologies, it’s now possible to engineer fiber architectures that offer strength, flexibility, and thermal stability—all in a single solution.

Ready to bring this performance to your next project? Contact our experts to discuss the most advanced composite solutions for your industry.

Digital Twin Technology and Predictive Modeling in Fiber Development

Another groundbreaking development in carbon fiber technology is the use of digital twin models—virtual replicas of manufacturing systems or components that simulate performance under various conditions. These tools enable engineers to test, refine, and optimize fiber placement, resin behavior, and curing techniques before physical production even begins.

By simulating the life cycle of a composite product, manufacturers can reduce time to market, lower material waste, and ensure component reliability. Digital modeling is becoming indispensable for sectors like aerospace and defense, where failure is not an option and materials must meet the highest standards of performance.

Innovation Is the Backbone of Carbon Fiber’s Future

As demand for lighter, stronger, and more sustainable materials grows, carbon fiber innovations are rising to meet the challenge. From robotic fiber placement to AI optimization, from hybrid materials to sustainable recycling methods, each breakthrough reinforces the material’s role as a foundation of 21st-century manufacturing.

At CarbonFiber.com, we are committed to offering only the highest-quality carbon fiber solutions—developed and manufactured using the latest technologies. Whether you’re designing a prototype or scaling up production, our expertise and innovation will elevate your results.

Don’t settle for outdated materials. Explore our catalog or reach out to our team to learn how our advanced carbon fiber products can power your next project.

FAQ

1. What are the latest technological innovations in carbon fiber production?

Recent carbon fiber innovations include robotic fiber placement, AI-driven quality control, sustainable recycling techniques, and hybrid composite development.

2. How is automation improving carbon fiber manufacturing?

Automation enables precise fiber alignment, reduces waste, and increases production speed—making carbon fiber more accessible across industries.

3. Why is carbon fiber considered a next-generation material?

Due to its exceptional strength, low weight, and thermal resistance, carbon fiber is ideal for aerospace, automotive, energy, and medical applications.

4. How is AI used in carbon fiber production?

AI enhances quality control by identifying defects, optimizing curing processes, and predicting material performance in real time.

5. What is a digital twin in composite engineering?

A digital twin is a virtual model that simulates the behavior of a component or system, allowing engineers to refine carbon fiber technologies before physical production.

6. Is carbon fiber production becoming more sustainable?

Yes. Technologies like pyrolysis and bio-based resins allow for fiber recycling and energy-efficient manufacturing, making carbon fiber more eco-friendly.

7. What are hybrid composites and why are they important?

Hybrid composites combine carbon fiber with other materials like Kevlar or fiberglass to create customized mechanical properties for specific applications.