Carbon fiber ranks among the most advanced materials in modern manufacturing. Thanks to its unmatched strength, low weight, and durability, it continues to revolutionize multiple industries. So, how is it made? Well, the manufacturing process is both complex and highly precise.

Moreover, it demands strict quality control at every stage to ensure the resulting composite materials meet the performance standards required in aerospace, automotive, sports, and medical industries.

In this guide, we’ll walk you through the carbon fiber manufacturing process step by step—from raw materials to the final product.

What Is Carbon Fiber Manufacturing?

Carbon fiber manufacturing involves converting organic polymer strands—typically PAN-based—into long, strong, and lightweight fibers. Manufacturers then weave these fibers and combine them with resins to produce high-performance composite materials. As a result, these composites are ideal for building parts that demand exceptional strength and minimal weight.

Raw Materials – PAN vs. Pitch

Most carbon fiber starts as polyacrylonitrile (PAN), a synthetic polymer known for its stability and strength. While some specialty carbon fibers come from pitch or rayon, PAN dominates over 90% of production thanks to its superior structural properties.

Initially, manufacturers spin the raw PAN fiber into long strands, forming the base for carbonization.

Stabilization

In this step, the process heats PAN fibers in air at approximately 200–300°C to change their molecular structure. As a result, this prevents the fibers from melting in the high temperatures used during carbonization.

Next, stabilization ensures that the material maintains its alignment and tensile properties before moving to the following step.

Carbonization

Carbonization is where the transformation into carbon fiber truly begins. Next, the process heats the stabilized fibers to temperatures between 1,000 and 3,000°C in a nitrogen

atmosphere. This process removes all non-carbon atoms, leaving behind a fiber that is over 90% pure carbon.

The result is a lightweight, strong, and thermally stable fiber with a distinctive black appearance.

Fiber Weaving and Layup

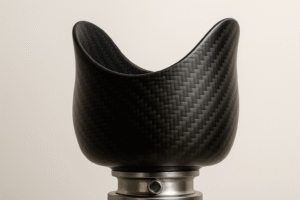

After producing the carbon fibers, the next step is weaving them into fabrics or bundling them into tows. These weaves can vary (plain, twill, satin) depending on the application. Then, the fabric layers are placed and aligned in molds during the layup process to optimize strength in targeted directions.

This stage determines the final geometry, texture, and strength of the product.

Resin Infusion or Prepreg Application

To turn carbon fiber fabric into a usable composite, it must be combined with a resin matrix, usually epoxy. There are two main approaches:

· Resin Infusion: The dry fabric is placed in a mold, and resin is vacuum-infused into the fibers.

· Prepreg (Pre-impregnated): The carbon fiber is pre-coated with resin and stored at low temperatures until it’s ready to be cured.

Both techniques create a strong bond between the resin and fiber, forming a solid composite material.

At Composite Manufacturing Inc., our unique carbon fiber manufacturing process enables us to produce elegant high-strength products that meet the most stringent industry standards. We use state-of-the-art equipment and proprietary technologies to create lightweight yet structurally superior designs.

Curing and Finishing

The composite is then cured in an oven or autoclave, where heat and pressure harden the resin, solidifying the final structure. This is a crucial step in developing the material’s final properties—strength, rigidity, and heat resistance.

Furthermore, after curing, the product undergoes several finishing processes, including:

- Trimming and shaping

- Surface coating

- Polishing or painting

The Role of Quality Control in the Production Process

Quality control is essential in every step of carbon fiber manufacturing. A single defect can compromise the strength and safety of the final product.

Key checkpoints include:

- Another key step is monitoring fiber alignment during weaving.

- Ensuring correct temperature and timing during carbonization and curing

- Testing resin distribution and bond integrity

- Inspecting finished parts with non-destructive testing methods like ultrasound or X-ray

Consistent QC ensures that the material performs as expected in demanding applications.

Common Challenges in Carbon Fiber Production

Despite its benefits, carbon fiber manufacturing is not without challenges:

- High costs: Equipment and energy demands are expensive.

- Material waste: Prepregs must be stored properly and used quickly to avoid expiration.

- Complex molding: Shaping carbon fiber into intricate geometries can be labor-intensive.

New manufacturing methods, such as automated fiber placement (AFP) and 3D carbon fiber printing, are being developed to address these issues.

Final Thoughts: The Future of Carbon Fiber Manufacturing

As innovation accelerates, the carbon fiber production process is becoming more efficient, automated, and eco-friendly. Manufacturers are working to reduce energy consumption, recycle offcuts, and scale production to meet growing demand in industries like aerospace, EVs, and medical devices.

Understanding how carbon fiber is made helps you appreciate the technology behind lightweight performance and durability.

Ready to Explore Custom Carbon Fiber Manufacturing?

At Composite Manufacturing Inc., we specialize in custom-engineered carbon fiber parts with unmatched strength, precision, and cosmetic quality. Whether you need aerospace components, medical-grade composites, or even more complex turnkey products — we are here to help you every step of the way.

Contact us for a quote and discover how we bring your designs to life with advanced carbon fiber manufacturing.