Looking for a powerful, portable way to cut through tough materials? A cordless bolt cutter might be the upgrade your toolbox needs. Whether you’re working on construction sites, rescue operations, or industrial maintenance, these battery-powered tools offer the strength of traditional cutters with unmatched mobility.

In this guide, we’ll break down everything you need to know about cordless bolt cutters—what they are, their key benefits, how to choose the best model, and how to keep yours performing at its best.

What Is a Cordless Bolt Cutter?

A cordless bolt cutter is a battery-powered cutting tool designed to cut through metal rods, chains, padlocks, and bolts. Unlike manual bolt cutters that require physical force, cordless models use an electric motor to deliver consistent cutting power—no outlet or muscle strain required.

Ideal for:

- Construction crews

- Emergency responders

- Utility maintenance teams

- DIYers looking for cutting convenience

Benefits of Using a Cordless Bolt Cutter

Portability for On-the-Go Jobs

Cordless tools offer maximum flexibility, especially in remote locations. Without a power cord, you can cut anywhere—from rooftops to roadside emergencies.

Faster Cutting, Less Effort

Powered by lithium-ion batteries, these tools slice through tough materials with minimal user effort, speeding up your workflow and reducing fatigue.

Versatility Across Applications

Cordless bolt cutters are ideal for a variety of tasks:

- Cutting rebar on construction sites

- Removing padlocks or chain links

- Performing tactical rescue operations

How to Choose the Best Cordless Bolt Cutter

Choosing the right model comes down to a few key considerations:

Battery Life & Power Output

Look for tools with long-lasting lithium-ion batteries and high voltage (typically 18V+). Some offer quick charge times and backup batteries for non-stop work.

Blade Quality

Opt for hardened steel blades—they stay sharp longer and resist damage from cutting dense or high-tensile materials.

Ergonomic Design

Choose a model with:

- Non-slip, rubberized grips

- Balanced weight distribution

- Safety switches or locks

These features reduce the risk of injury and improve comfort during extended use.

Top Applications for Cordless Bolt Cutters

Construction & Demolition

Cordless models are perfect for cutting rebar, fencing, or metal fasteners on-site, helping you stay efficient without needing power access.

Emergency Rescue & Tactical Use

Quick access is crucial in emergencies. Cordless bolt cutters help first responders cut locks, chains, and barriers with speed and precision.

Industrial Maintenance

Technicians use cordless cutters to quickly remove old bolts, pipes, or security fittings, streamlining repair tasks in factories and warehouses.

Cordless vs. Traditional Bolt Cutters

| Feature | Cordless Bolt Cutter | Manual Bolt Cutter |

|---|---|---|

| Power Source | Battery-powered | Manual effort |

| Portability | High | Medium |

| Cutting Efficiency | Fast, consistent | Slower, requires more strength |

| Ideal For | Professionals, frequent use | Occasional, light-duty use |

Bottom line: Cordless bolt cutters are ideal for heavy-duty, frequent use. Manual ones may be sufficient for light or rare cutting needs.

Maintenance Tips for Longevity

Keep your cordless bolt cutter in top shape with these simple practices:

Battery Care

- Use the original charger.

- Avoid overcharging.

- Store in a cool, dry place.

Blade Maintenance

- Inspect blades for dullness or wear.

- Sharpen or replace as needed.

- Use only on recommended materials.

Cleaning & Storage

- Wipe down after use.

- Lubricate moving parts.

- Store in a moisture-free case or toolbox.

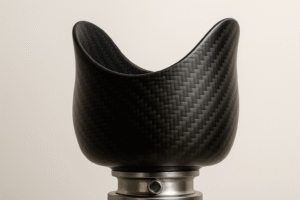

Why Composite Manufacturing Materials Matter

Many high-performance cordless bolt cutters now feature composite components—materials that are:

- Lighter than steel

- Resistant to corrosion

- More durable under intense use

These advanced materials reduce fatigue and extend the tool’s lifespan, making them a smart choice for professionals.

Frequently Asked Questions (FAQ)

How long does the battery last on a cordless bolt cutter?

It depends on the model and how you use it, but most cordless bolt cutters can run for 2 to 4 hours on a full charge. If you’re doing heavy-duty work, that time might be a bit shorter—but many models come with extra batteries or fast-charging options, so you won’t be stuck waiting.

Can a cordless bolt cutter handle hardened steel?

Yes, many can! Just make sure the one you choose is rated for cutting high-tensile or hardened steel. That usually means it has strong, hardened blades and enough power to get through tough materials safely.

Is it safe to use a cordless bolt cutter indoors?

Definitely. Since it’s battery-powered, there are no fumes or loud engines to worry about. It’s a great option for using in garages, workshops, or even inside buildings, as long as you follow basic safety tips.

Ready to Upgrade to a Cordless Bolt Cutter?

If you’re looking for a cutting tool that combines power, speed, and freedom of movement, a cordless bolt cutter is the clear choice.

At Composite Manufacturing, we offer custom solutions that integrate high-performance materials for unmatched durability and user comfort.

Explore our latest models or request a personalized quote today!

Let us help you cut faster, safer, and smarter.