Did you know carbon fiber medical devices can be up to 50% lighter than traditional equipment without sacrificing strength or performance? As healthcare technology continues to evolve, carbon fiber has emerged as a groundbreaking material that’s transforming how medical devices are designed, manufactured, and used. From surgical tables to prosthetic limbs, carbon fiber is revolutionizing the healthcare industry with lightweight, durable, and radiolucent solutions that enhance both patient care and clinical precision.

Why Carbon Fiber is Changing the Medical Device Industry

Strength & Durability for Demanding Medical Environments

Carbon fiber is known for its exceptional strength-to-weight ratio. Unlike conventional metals like stainless steel or aluminum, it resists pressure, repetitive use, and wear over time—making it ideal for surgical instruments, orthopedic braces, and diagnostic equipment that must endure high performance and daily sterilization.

Lightweight Design Enhances Usability

In high-stakes healthcare settings, ease of use is critical. Carbon fiber’s lightweight nature reduces strain on medical professionals during long procedures and improves device maneuverability in fast-paced environments. Whether lifting a surgical table component or repositioning a patient, the reduced weight increases efficiency without compromising safety.

Corrosion Resistance for Long-Term Reliability

Unlike metal-based tools prone to rust or degradation, carbon fiber is inherently resistant to corrosion. This makes it particularly valuable in sterile or high-moisture environments like operating rooms, where device longevity and hygiene are critical.

Request a quote now and explore how carbon fiber can transform your healthcare operations.

Key Benefits of Carbon Fiber Medical Devices

Enhanced Comfort for Patients & Surgeons

- Lighter equipment means easier handling and setup, reducing physical strain on medical staff.

- Patients benefit from devices that are less bulky and more precise, leading to shorter recovery times and more personalized care.

Superior Strength-to-Weight Ratio

- Stronger than steel but significantly lighter, carbon fiber medical devices are ideal for prosthetics and orthopedic supports that must be both durable and flexible.

- These devices can bear substantial weight while remaining portable and ergonomic.

Radiolucency for Imaging Applications

- Carbon fiber is radiolucent, meaning it doesn’t interfere with X-rays or fluoroscopy.

- It enables clearer diagnostic imaging, especially in CT and MRI scans, and eliminates visual distortion common with metal parts.

Common Applications of Carbon Fiber in Medicine

Surgical Tables & Accessories

- Carbon fiber operating tables offer imaging compatibility, precise positioning, and structural strength.

- Radiolucent handboards and arm supports improve intraoperative imaging and patient access during surgery.

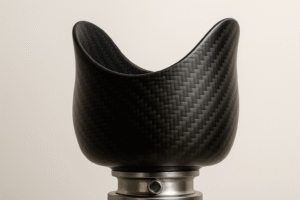

Prosthetics & Orthotics

- Ultra-lightweight carbon fiber prosthetic limbs increase mobility and reduce fatigue.

- Durable orthopedic braces provide long-term support without the bulk of traditional materials.

Diagnostic & Imaging Equipment

- Carbon fiber X-ray tables maintain image clarity while supporting patients securely.

- Radiation shields and positioning devices help protect staff and patients without compromising scan quality.

Surgical Instruments & Robotics

Carbon fiber components are now used in robot-assisted surgery and handheld tools, allowing for precise, vibration-resistant movements with minimal weight. This enhances both surgeon performance and patient outcomes.

Get in touch for a personalized consultation with our experts.

Why Manufacturers Choose Carbon Fiber for Medical Devices

Greater Efficiency & Performance

- The lightweight design reduces handling time and simplifies sterilization processes.

- Enhanced maneuverability and reduced fatigue lead to higher procedure accuracy and better results.

Long Lifespan = Lower Costs

- Carbon fiber resists corrosion, cracking, and fatigue, meaning fewer replacements and less maintenance.

- It’s a cost-effective investment in long-term operational performance.

Sustainability in Healthcare

- Carbon fiber is more environmentally friendly than many metals due to its extended lifecycle and lower need for frequent replacement.

- As hospitals aim for greener practices, carbon fiber aligns with eco-conscious procurement strategies.

Choosing the Right Carbon Fiber Medical Devices

What to Look For:

- Material quality: Ensure true carbon fiber composition—not just carbon-coated components.

- Medical certification: Devices should meet FDA or CE regulations for safety and use in clinical settings.

- Customization options: Some applications require tailored solutions to meet specific surgical or patient care needs.

Why U.S. Manufactured Carbon Fiber Devices Stand Out

U.S.-based manufacturers often offer:

- Stricter quality control

- Faster lead times

- Compliance with domestic healthcare regulations

Looking Ahead: The Future of Carbon Fiber in Medicine

As technology progresses, expect to see carbon fiber integrated into more surgical robots, diagnostic tools, and patient care systems. Its combination of strength, flexibility, and biocompatibility is driving innovations that prioritize safety, precision, and performance.

Be a Part of the Future of Healthcare

Carbon fiber medical devices are not just an innovation—they are the new standard. Whether you’re equipping an operating room, designing advanced prosthetics, or upgrading diagnostic imaging systems, carbon fiber provides unmatched performance and value.

At Composite Manufacturing, we engineer custom carbon fiber solutions with the highest structural and cosmetic precision. Ready to upgrade your medical equipment?

Contact us today to explore our advanced carbon fiber products and request a tailored quote.