What Are Carbon Fiber Medical Devices and Why They Matter

Carbon fiber medical devices are advanced tools and equipment made from high-strength, lightweight carbon fiber composites. These solutions are transforming healthcare by introducing innovations that improve patient outcomes, procedural efficiency, and ergonomics. Designed to replace traditional materials like metal and plastic, carbon fiber in medical devices offers greater durability, reduced weight, and better imaging compatibility. For hospitals, clinics, and OEMs, selecting the right carbon fiber medical device supplier or manufacturer can significantly impact quality and performance.

Comparing Carbon Fiber and Conventional Medical Components

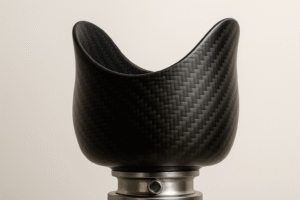

In a material comparison for surgical and diagnostic use, carbon fiber frequently outshines aluminum and stainless steel. Its exceptional strength-to-weight ratio and rigidity make it ideal for imaging tables, orthopedic braces, and prosthetic components. At CarbonFiber.com, our offerings demonstrate how carbon fiber medical devices solutions can replace heavier equipment without compromising function. Radiolucent carbon fiber ensures X-ray and CT imaging clarity—unlike metal parts that interfere with scans. This property alone makes carbon fiber medical devices indispensable in modern medical environments. You can explore our real product range in the Medical Devices section.

Why Lightweight Design Matters in Healthcare Applications

Doctors and clinicians appreciate carbon fiber medical devices because of their lightness. Carbon fiber reduces fatigue and strain during long procedures. Lightweight carbon fiber in medical devices also simplifies handling and sterilization, speeding up workflow and increasing safety. For example, carbon fiber operating tables and hand supports are easier to position and clean, enhancing efficiency. Check out products like the Microsurgical Arm & Hand Table made with high-quality carbon fiber and designed for real clinical use.

Radiolucency: Clear Imaging Without Obstructions

One of the key advantages of carbon fiber medical devices is their radiolucent nature. Devices made from carbon do not block X-rays or interfere with medical imaging. This is essential in examination tables, limb supports, and radiotherapy holders. In contrast, metals may create visual artifacts. With carbon fiber medical devices solutions, you can rely on equipment that allows clear visualization without compromising safety or design. Visit our Advanced Medical Solutions section for more real-world examples.

Durability and Chemical Resistance Keep Devices Reliable

Carbon fiber is highly resistant to corrosion and chemical wear. Unlike steel or aluminum, it won’t oxidize when exposed to disinfectants or humid environments. This makes carbon fiber medical devices wholesale a long-term investment. These components endure frequent cleaning, intensive use, and sterilization without degrading. When buying from a trusted carbon fiber medical devices supplier like us, you get consistent quality and low replacement needs.

Customization: Tailored Carbon Fiber Medical Device Solutions

Every medical project has unique needs. Our experience as a carbon fiber medical devices manufacturer allows us to create custom solutions. Whether it’s a custom surgical arm support or prosthesis, we use CAD design and rapid prototyping to meet your specifications. We also work with regulatory and biocompatibility standards, ensuring clinical-grade quality. Explore our “Custom Composite Solutions” section on the site to see how we can support specific projects.

Biocompatibility: Safe for Long-Term Use in Patients

Carbon fiber medical devices must meet medical standards. Many implants made from carbon fiber—like spinal plates or prosthetics—have proven safe and compatible with the human body. While some implants require chemical coatings for better integration, their carbon base reduces weight, enhances rigidity, and provides reliable clinical outcomes. Radiolucent and durable devices also enable more efficient and less invasive care.

Cost vs Value: Why Carbon Fiber Deserves Consideration

Carbon fiber for medical devices typically costs more than metal alternatives, but its long-term value offsets the price. Less weight means less physical strain for medical staff, less wear on equipment, and fewer replacements. It also improves clinical accuracy. Our role as supplier and manufacturer is to offer competitive prices with high durability. Request a quote quickly from our Contact Us page.

Applications: Where Carbon Fiber is Changing Healthcare

Carbon fiber is now used in surgical tables, limb supports, custom prosthetics, positioning devices, and more. According to market research, the use of carbon fiber in medical devices is growing in minimally invasive procedures, radiology, and rehabilitation. At CarbonFiber.com, we develop components for imaging equipment, OR systems, and mobility devices that meet strict tolerances and ergonomic design. Review our capabilities in the About Us section to learn more about our expertise in medical devices.

Emerging Trends: 3D Printing and Hybrid Composites in Medical Use

Innovations like 3D printing with reinforced fiber and hybrid materials are accelerating the development of custom carbon fiber medical devices. This enables the creation of complex implants and custom tools that perfectly fit patient anatomy. The combination of carbon fiber with advanced polymers provides rigidity, lightness, and biocompatibility. These technologies are emerging as groundbreaking solutions in the medical sector, supported by our line of carbon fiber medical devices solutions.

Challenges: Manufacturing and Regulatory Considerations

Manufacturing medical devices with carbon fiber presents challenges: higher costs, curing processes, quality control, and regulatory requirements such as FDA approval. However, the industry is advancing with fast-curing resins, advanced cleaning, and testing systems. As a specialized manufacturer, we work with internal quality control teams and processes designed to meet medical regulations. This ensures every carbon fiber medical device is safe, durable, and approved for clinical use.

Why Choose Our Carbon Fiber Medical Devices Supplier

Our commitment is to deliver reliable, customized, and technically advanced solutions. We are a carbon fiber medical devices manufacturer and supplier with FDA certification and over 40 years of experience serving the medical sector. Our vertically integrated production model means full control from design to assembly. This results in superior quality, fast lead times, and competitive prices. Contact us directly to learn more or request a custom quote.

How to Start Your Project with Carbon Fiber Devices

If you’re developing a new medical device or upgrading an existing one, integrating carbon fiber medical devices can make a difference. First, define technical needs: weight, biocompatibility, imaging, stiffness. Then evaluate prototypes or existing products like radiolucent tables or custom supports. Finally, we work with you to produce devices that meet your functional and regulatory needs. Initial consultations are free—just visit our Contact Us page and share your project.

Conclusion: Transform Your Medical Devices with Carbon Fiber

In summary, carbon fiber medical devices represent a major advancement in healthcare: they combine lightness, durability, biocompatibility, and imaging compatibility. Compared to traditional materials, they offer better ergonomics, less wear, and greater clinical precision. As a custom carbon fiber medical devices manufacturer and supplier, CarbonFiber.com offers made-to-order, scalable solutions ready for real medical use. Explore our medical products or contact us today to collaborate on your next innovation.